Description

Pall Coalescer Filters

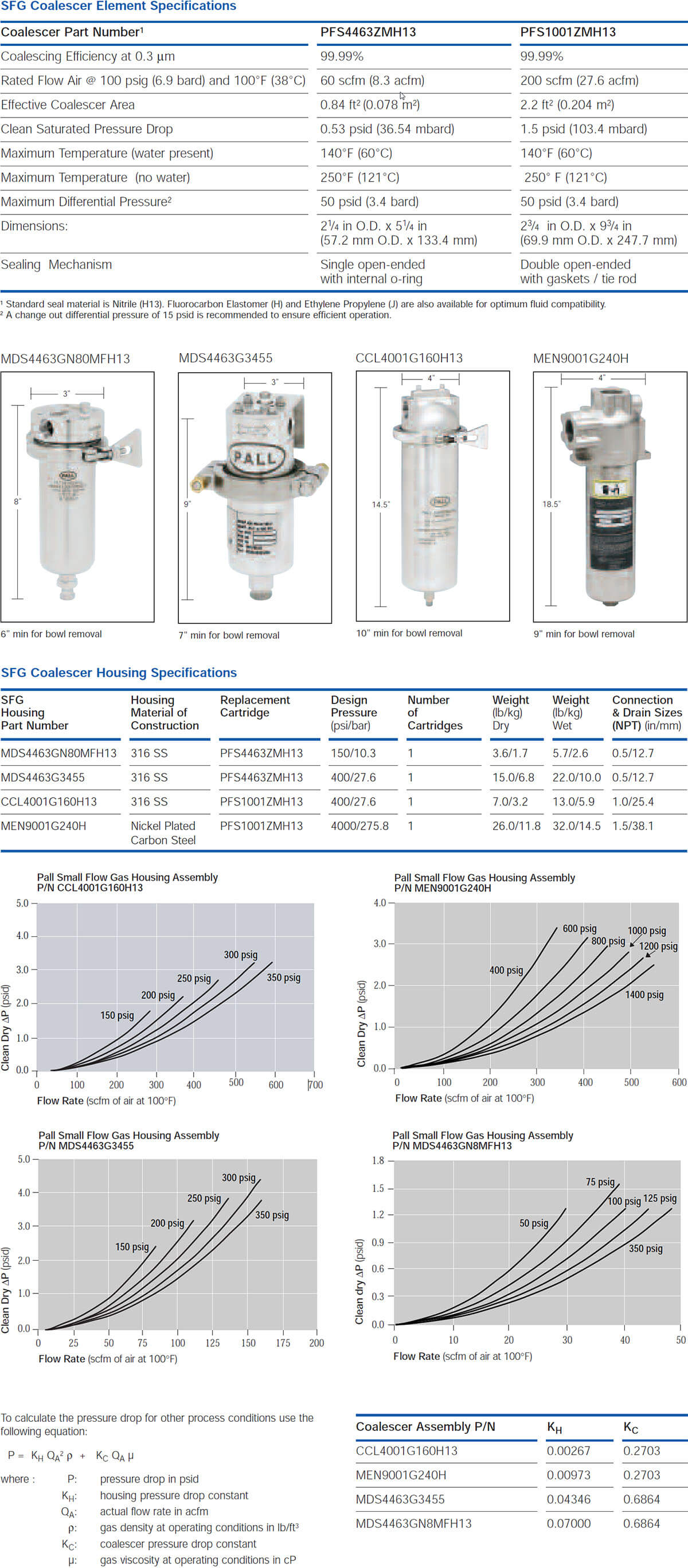

Small Flow Gas Coalescing Assembly

The Small Flow Gas Coalescing Assembly are a rugged, inexpensive, high efficiency assembly that eliminate problems caused by oil, water, and dirt in air or gas.

Performance Specifications

- Removal of 99.99% of all aerosols 0.3 microns and larger. Typical downstream aerosol concentrations are less than 0.003 ppm.

- Patented surface treatment that prevents liquids from wetting the coalescer media allowing for higher gas flow capacity and lowered fouling tendency and differential pressure.

- Consistent performance using thin fibers and fixed pore construction optimized for efficient coalescing.

- Long service life due to pleated media structure and surface treatment.

- Low energy losses with typical saturated pressure drop of 1.2 psid (82.7 mbard).

- Wide range of compatibility for use with process gases, compressor oils, hydrocarbon condensates, and water.

SFG Coalescer Features

Positive Seal: Standard seal material is Nitrile (H13) available as either an internal o-ring or flat gasket depending on coalescer size.

Outer Drainage Layer: Drainage of coalesced liquid and protection from re-entrainment is provided by a polymeric outer drainage layer. This ensures consistent, high efficiency performance.

Metal Support Core: Axial strength and protection against liquid slugs are provided by a perforated inner support core constructed of 304 stainless steel.

Outer Cage: Media support during operation is provided by a 304 stainless steel outer support cage.

Primary Coalescer: Coalescing is achieved by use of a high area pleated glass fiber medium that is surrounded by a non-woven polymeric support and drainage layers. A patented surface treatment is used that enhances coalescer performance and lowers fouling tendency and pressure drop.

End Caps: 304 stainless steel end caps are used to improve cartridge strength and prevent contaminant bypass.

Key Benefits

- Protects process analyzers.

- Safeguards instrument air operated equipment and systems.

- Prevents orifice plugging in pneumatic controllers.

- Improves accuracy of gas measurements in the field or plant.

- Decreases freeze-out and corrosion problems.

- Reduces fouling in small gas-driven engines.

- Provides reproducible high-quality gas for all operations sing produced gas.