Description

Pall Coalescer Filters

AquaSep XS Coalescers

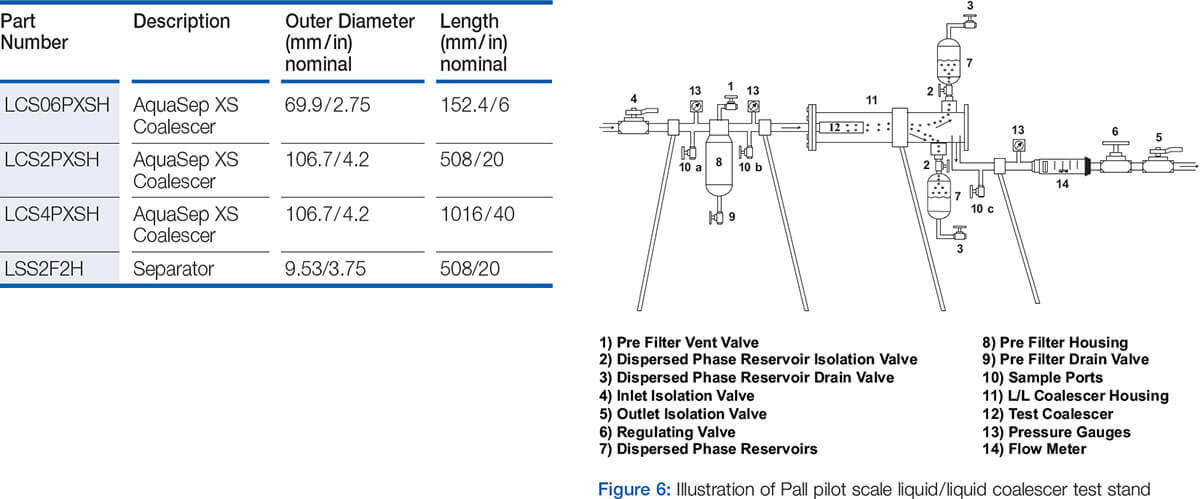

Pall’s new AquaSep XS coalescers are a liquid/liquid coalescer system that is a lower cost solution to separate emulsions versus competitive cartridge coalescers and other traditional methods. Its cost effectiveness is due to the ability of each coalescer element to process a higher flow while still providing superior effluent quality. For existing cartridge coalescer systems, the AquaSep XS element provides superior removal of slugs of liquid contaminant thereby making it a more reliable solution than competitive offerings. See Figures 1, 2, and 3 below.

Typical Applications

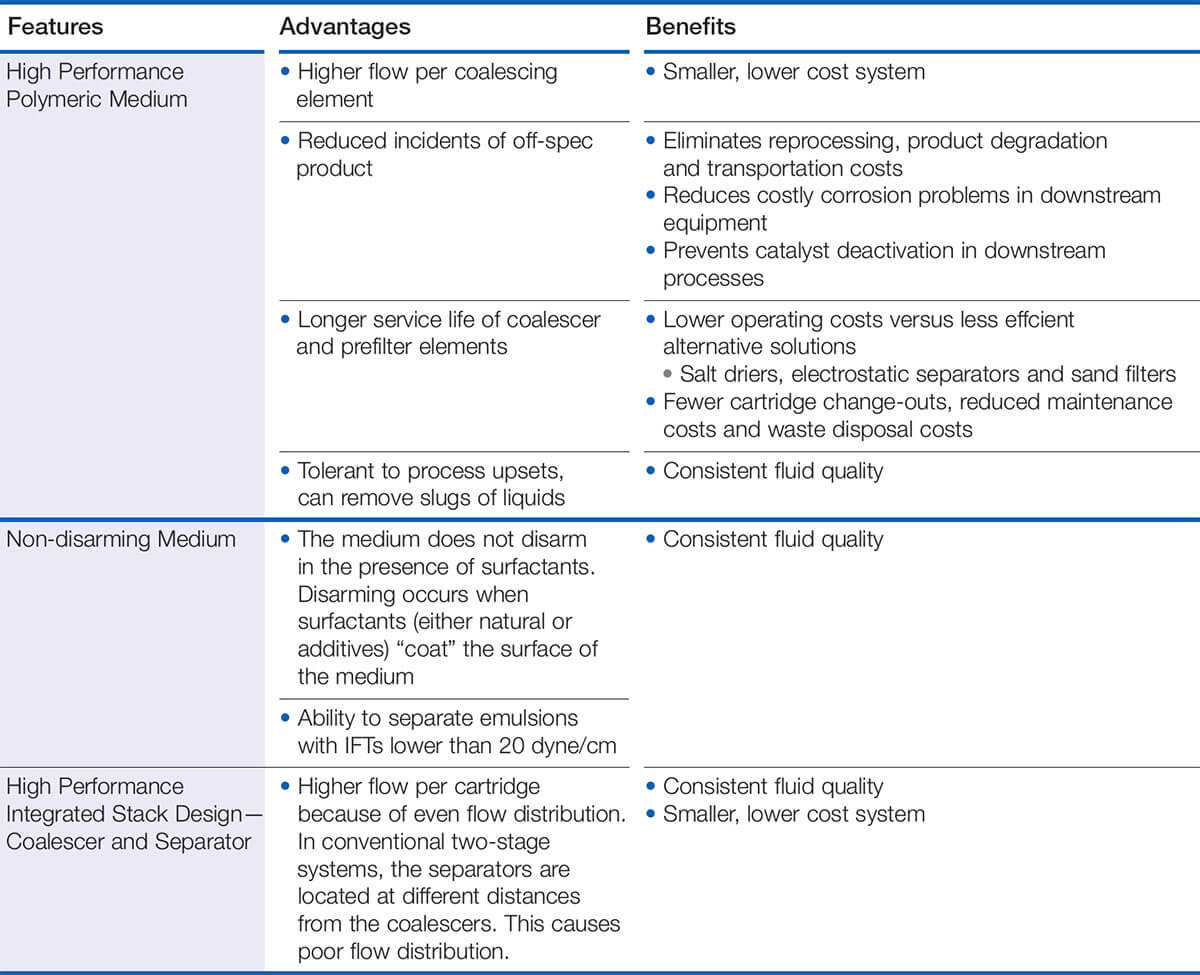

Not all coalescers provide a high quantitative removal of dispersed liquid contaminants and can handle emulsions with low interfacial tensions (IFTs). For example, conventional cartridge coalescers made of glass fiber media begin to lose efficiency when the IFT of the emulsion gets below 20 dyne/cm. In contrast, the new AquaSep XS coalescer from Pall is constructed of a high-efficiency, polymeric medium, making it well suited for numerous liquid/liquid separation applications with very low IFTs including:

- Removal of water from refined products including gasoline, diesel, kerosene, and LPG.

- Separation of water from hydrocarbon condensates.

- Separation of oil from water.

- Removal of water from aromatics.

Comparative Performance

NOTE: Comparison tests were performed in a Pall laboratory with a limited number of 20 inch elements that were purchased through standard commercial channels. Lab results may not be identical to test results with actual process fluid under field conditions.

Benefits of the AquaSep XS Coalescers

Description

The AquaSep XS system is a multiple-stage system starting with filtration to remove particulate matter, followed by either a one-stage or two-stage integrated coalescer stack to separate the two liquid phases. AquaSep XS coalescers will remove free water to a level as low as 15 ppmv1 and be effective over a wide range of conditions such as inlet liquid contaminant concentration as high as 10% and interfacial tension less than 20 dyne/cm.

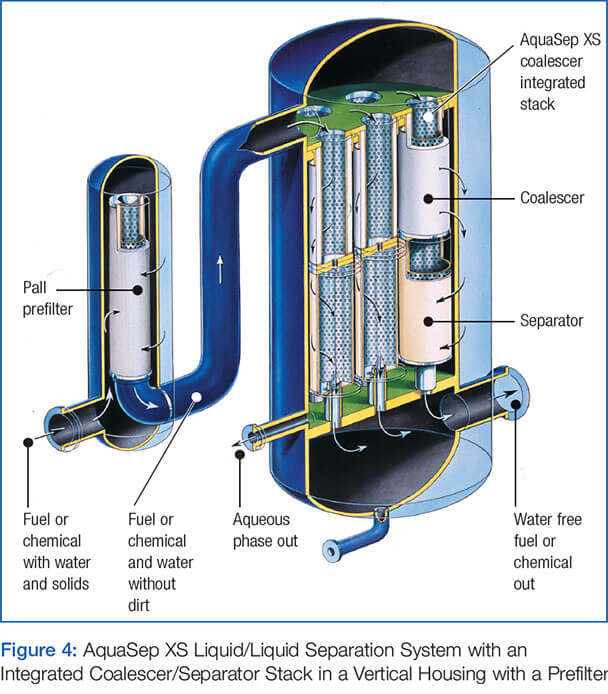

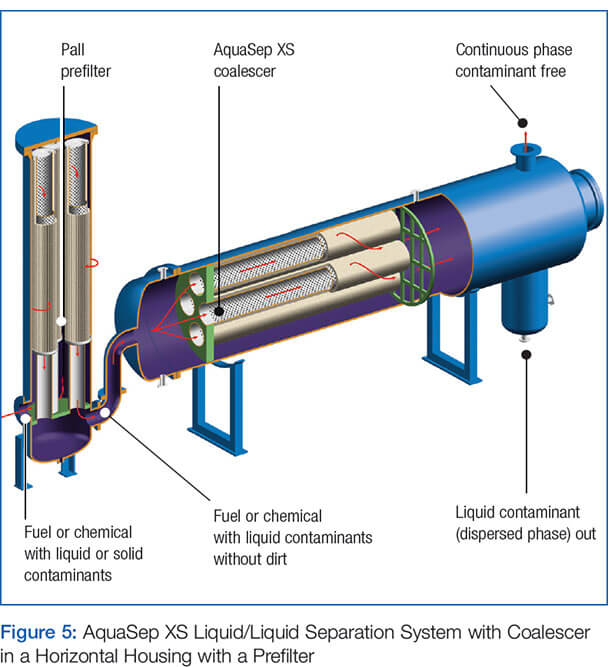

The AquaSep XS coalescer system is available in two different housing configurations. Both configurations begin with a filtration stage to remove solid contaminants.

AquaSep XS Coalescer/Separator Stack – Vertical Housing Configuration

The liquid/liquid mixture enters the coalescing element and flows inside-to-outside. Small liquid droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the coalescer medium.

Contaminant-free liquid and large droplets of the dispersed phase flow toward the separator located directly below the coalescer stage. The flow is outside to inside. The separator medium is hydrophobic preventing the aqueous phase from entering the separator. Only the non-aqueous continuous phase fluid flows through the separator. The two liquids are removed by separate drain connections.

AquaSep XS Coalescer – Horizontal Housing Configuration

In a horizontal housing, the liquid/liquid mixture enters the coalescing element and flows inside-to-outside, small liquid dispersed phase droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the AquaSep XS coalescer. The large coalesced droplets of the dispersed phase separate by gravity in the horizontal housing and are removed. The size of the housing is a function of the flow rate, IFT, viscosity, and specific gravity of the liquids.

Compatibility

The AquaSep XS coalescer is compatible with hydrocarbon fuels, trace amounts of IPA and methanol, and water in the pH range of 4 – 8.5. For compatibility information with a specific chemical, please contact your Pall representative or distributor.

AquaSep XS Coalescer Reduces Costs

Begin reducing your capital and operating costs today. Contact your local Pall distributor or call Pall directly to arrange for a budgetary quotation and pilot test of the AquaSep XS coalescer technology.

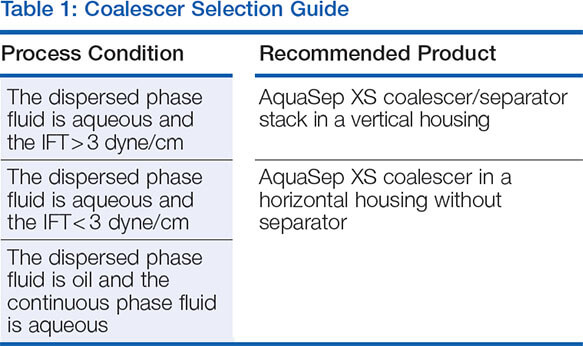

Ordering Information